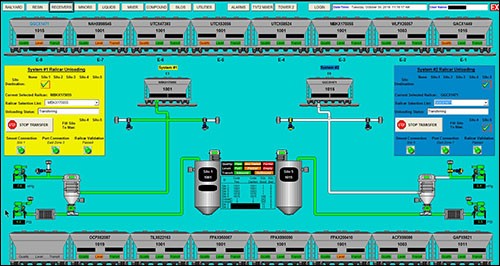

Aurora Plastics has adopted a system from Quest Integrated Solutions, using Jamam hardware, that not only helps prevent costly mistakes in the process of off-loading plastic resin, but also improves rail-yard management.

Nov 02, 2018—

Thermoplastic compounds company Aurora Plastics has boosted its resin-unloading and yard-management efficiency, while also preventing unloading errors, by deploying a radio frequency identification solution provided by Quest Integrated Solutions, a division of Technology Recovery Group (TRG). The system employs RFID reader hardware supplied by Janam Technologies.

Founded in 1997 and based in Streetsboro, Ohio, Aurora Plastics develops and manufactures polymer compounds customized for a variety of applications, such as building and construction, recreational, automotive, wire and cable, hose and tube, batteries and footwear. The firm manufactures rigid and flexible PVC compounds, thermoplastic elastomers, custom thermoplastic olefins, CPE alloys, PVC-acrylic alloys, low-smoke zero-halogenated compounds, flame-retardant concentrates, SBS and SEBS compounds, and PVC and TPE cellular foam compounds.

Source: Plastics Company Prevents Errors With RFID – 2018-11-02 – Page 1 – RFID Journal