By the AIM North America Food Supply Chain Working Group

September is National Food Safety Education Month, focusing on the importance of food safety and the innovative technologies that support it. A key technology in this field is RAIN, which AIM North America‘s Food Supply Chain Working Group leverages to emphasize improvements in traceability, efficiency, and sustainability within the food industry.

The Role of RAIN in Food Safety

RAIN technology is vital to modernizing food safety by providing accurate, real-time data, improving traceability, and supporting sustainability. Here’s how RAIN is making a difference:

- Enhanced Supply Chain Visibility

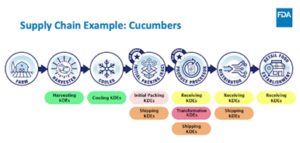

RAIN offers real-time data capture for inventory management and supply chain visibility, helping businesses comply with regulations like the Food Safety Modernization Act (FSMA) 204 and the Digital Product Passport (DPP). By tracking products from farm to table, RAIN reduces foodborne illness risks by identifying contaminated products and facilitating rapid recalls. It automates data collection, reduces human error, and ensures compliance with minimal labor impact.

An example of RAIN’s impact is the collaboration between Subway-IPC, GS1 US, and Avery Dennison. Their case study shows how IPC, the purchasing cooperative of Subway, used RAIN and GS1 Standards to achieve end-to-end traceability throughout the supply chain. This resulted in $1.3 million in annual cost savings and improved food safety through quicker, more precise recalls.

In addition, Chipotle is scaling up its use of RAIN to trace ingredients from suppliers to restaurants in real-time and strengthen its inventory systems in partnership with Trustwell. Their case study demonstrates that good visibility of the value chain is vital if something were to happen you can address the problem right then and there. This investment saved suppliers time on inventory management and stock rotation, mitigate human error, and increase expiration date visibility and accountability.

- Proactive Food Safety Management with Cloud Technology and Predictive Analytics

Combining RAIN with cloud technology and predictive analytics provides enhanced insights. Cloud-based platforms aggregate data from RAIN tags, temperature sensors, and shipment records, predicting when and where products might spoil. This predictive capability supports high standards like Hazard Analysis and Critical Control Points (HACCP), enabling companies to take proactive measures to avoid contamination, reduce waste, and ensure food safety.

- Connected Products for Traceability and Sustainability

RAIN-enabled intelligent labels enhance traceability, reduce waste, and promote sustainability in the food industry. These labels provide critical information about a product’s journey through the supply chain, meeting standards like FSMA 204. They help track product movement, ensure proper handling, and manage recalls effectively. Additionally, these labels reduce waste by offering accurate information on shelf life, allowing for better inventory management and sustainable choices.

AIM Food Supply Chain Working Group Activities

The AIM North America Food Supply Chain Working Group is dedicated to promoting food safety and RAIN adoption through various initiatives:

- Opposition to IFPA Percentage-Based Lot Traceability Proposal

AIM opposes the International Fresh Produce Association (IFPA)’s proposal for percentage-based lot traceability. AIM argues that this approach could introduce inconsistencies, reduce precision, and potentially compromise consumer safety. Instead, AIM supports RAIN and intelligent labeling technologies for real-time, item-level tracking to ensure compliance with FDA requirements and maintain high food safety standards.

- Response to HR Bill on FSMA 204

The AIM Working Group actively engages with stakeholders regarding United States Congressional Bill HR 7563, the Food Traceability Enhancement Act, which seeks to relax recordkeeping and traceability requirements. AIM opposes this bill, believing it undermines the FDA’s Food Traceability Final Rule and the goals of FSMA 204. The group continues to advocate for stringent traceability standards leveraging technologies like RAIN that support consumer safety.

- Speaking Opportunities: RFID Journal LIVE, GS1 Connect, Food Safety Summit, Food Safety Consortium, Labelexpo, PACK EXPO, and more

AIM’s Working Group participates in several industry events, highlighting how RAIN technologies help food companies comply with regulations, enhance traceability, and improve safety. These events provided a platform to discuss the latest developments in RAIN technology and its applications in the food industry.

- Educational Materials on FSMA 204

AIM has developed a range of educational materials and webinars to support the industry’s understanding of FSMA 204 and other food safety regulations. These resources offer insights into the requirements of FSMA 204 and best practices for implementation including leveraging RAIN.In addition, the upcoming issue of AIM’s Solutions Showcase, a bimonthly e-publication distributed to more than 19,000 individuals, spotlights member products and solutions. The 26 September special edition focuses on available resources in recognition of Food Safety Education Month – Safe Food Now for a Healthy Tomorrow.

Conclusion

As we celebrate National Food Safety Education Month, RFID technologies are crucial for enhancing food safety across the supply chain. From providing real-time data to supporting predictive analytics, RAIN is indispensable for meeting today’s food safety standards.

AIM North America’s Food Supply Chain Working Group remains committed to advancing these technologies through advocacy, education, and engagement. By promoting RAIN adoption, we aim to ensure a safer, more transparent, and sustainable food supply chain.

For more information on AIM North America’s Food Safety initiatives, visit our website.