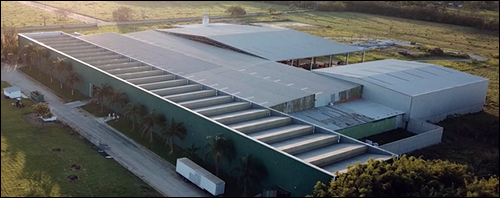

Thanks to improved production and inventory-management processes, Brazil’s R2A has optimized its entire end-to-end supply chain.

Jan 06, 2020—

By deploying a radio frequency identification system provided by iTag, Brazilian automotive parts manufacturer R2A reports that it has achieved high gains in its operations. Acting as a supplier of bumpers for various models and colors of cars manufactured in that country, the company says it achieved a 6 percent savings in raw materials due to better production planning.

Other benefits of the company’s use of RFID include increased inventory visibility; better identification of production batches due to unique ID codes provided by RFID tags; greater speed in locating products in stock; 100 percent accuracy in order picking and truck shipping processes; a 95 percent reduction in delivery errors, providing a savings of 85,000 Brazilian real ($20,750) per year; and real-time inventory updates.

More …

Source: RFID Saves Auto Parts Factory Money on Raw Materials – 2020-01-06 – Page 1 – RFID Journal